Description

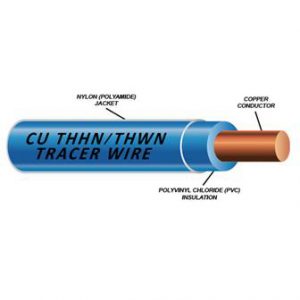

(NEW & IMPROVED) PRO-TRACE HDD-CCS PE45 tracer wire has almost 7X the break load of copper, which allows 1 wire to be installed in directional boring and pipe bursting applications . This tracer wire provides the perfect balance between strength, ductility, and brittleness to ensure durability. When copper tracer wire is used, 2 to 5 wires may be used to obtain the needed strength to prevent breakage. In comparison, using 1 wire of 12, 10, or 8 AWG HDD-CCS is successful and costs substantially less. Bottom line is PRO-TRACE HDD-CCS tracer wire is superior to copper in strength and durability. Take a look at some of the advantages.

-

-

- Designed for directional boring or pipe bursting using 1 wire

- Perfect Balance Between Tensile Strength, Ductility, and Brittleness

- Has up to 7X (or 700%) the break load of Copper

- Corrosion Resistant Properties of Copper

- Tracer Wire Performance Equal to Copper

- High-Density, HMWPE Insulation, and Direct Burial Rated

- Significantly Lower in Cost and Great Price Stability

- Most Durable Tracer Wire on the Market

-

-

-

-

ASTM B910 / B190M: Standard Specification for Annealed Copper-Clad Steel Wire.

- ASTM B170: Standard Specification for Oxygen-Free Electrolytic Copper.

- ASTM D1248: Standard Standard Specification for Polyethylene Plastics Extrusion Materials For Wire and Cable

-

-

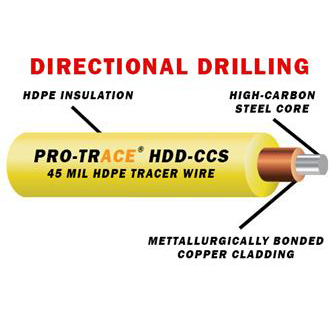

PRO-TRACE HDD-CCS PE45 is an extra high-strength, copper clad steel tracer wire. A high carbon steel core, metallurgically bonded with a copper cladding, that is uniform and continuous, creating a bi-metal conductor that acts as one and is corrosion resistant. The extreme break load allows only 1 conductor to be used in any tracer wire application for directional drilling (boring) or pipe bursting. It provides the perfect balance between break load, ductility, and decreased brittleness. It is the best performing tracer wire on the market for mechanical strength.

PRO-TRACE HDD-CCS PE45 uses a thicker, 45 mil, high-density, high molecular weight polyethylene (HDPE) insulation for extra protection in demanding installs. HDPE provides an excellent balance of surface smoothness, processing ease and electrical consistency. HDPE provides superior strength against underground elements that help prevent accidental breaks caused buy rocks in shifting soil conditions.

Tracer wire for directional boring installation shall be a 14 AWG solid, PRO-TRACE HDD-CCS PE45. Conductor shall be hard-drawn, 21% IACS, copper-clad steel, utilizing a AISI 1065 high carbon steel core with minimum break load of 855 lbs or 265,000 psi (required to meet break load). Conductor shall be extruded with a 45 mil, high density, high molecular weight polyethylene (HMW-HDPE) persuant to ASTM D1248. Tracer wire shall be rated for direct burial use at 30 volts and RoHS compliant. Tracer wire shall be PRO-TRACE HDD-CCS PE45 as manufactured by Pro-Line Safety Products.

Tracer wire for directional boring installation shall be a 12 AWG solid, PRO-TRACE HDD-CCS PE45. Conductor shall be hard-drawn, 21% IACS, copper-clad steel, utilizing a AISI 1055 high carbon steel core with minimum break load of 1,330 lbs or 260,000 psi (required to meet break load). Conductor shall be extruded with a 45 mil, high density, high molecular weight polyethylene (HMW-HDPE) persuant to ASTM D1248. Tracer wire shall be rated for direct burial use at 30 volts and RoHS compliant. Tracer wire shall be PRO-TRACE HDD-CCS PE45 as manufactured by Pro-Line Safety Products.

Tracer wire for directional boring installation shall be a 10 AWG solid, PRO-TRACE HDD-CCS PE45. Conductor shall be hard-drawn, 21% IACS, copper-clad steel, utilizing a AISI 1055 high carbon steel core with minimum break load of 1,940 lbs or 238,000 psi (required to meet break load). Conductor shall be extruded with a 45 mil, high density, high molecular weight polyethylene (HMW-HDPE) persuant to ASTM D1248. Tracer wire shall be rated for direct burial use at 30 volts and RoHS compliant. Tracer wire shall be PRO-TRACE HDD-CCS PE45 as manufactured by Pro-Line Safety Products.

Tracer wire for directional boring installation shall be a 8 AWG solid, PRO-TRACE HDD-CCS PE45. Conductor shall be hard-drawn, 21% IACS, copper-clad steel, utilizing a AISI 1065 high carbon steel core with minimum break load of 2,785 lbs or 215,000 psi (required to meet break load). Conductor shall be extruded with a 45 mil, high density, high molecular weight polyethylene (HMW-HDPE) persuant to ASTM D1248. Tracer wire shall be rated for direct burial use at 30 volts and RoHS compliant. Tracer wire shall be PRO-TRACE HDD-CCS PE45 as manufactured by Pro-Line Safety Products.