Description

2.4kV. Type MV-105 or MC. Copper Conductors. Thermosetting Conductor Shield. EPR Insulation (133%). Non Shielded. Copper Ground Wire. Aluminum Armor. PVC Jacket. Limited to 2,400 Volts Maximum.

APPLICATIONS

Southwire AL09ENS Type MV-105 or MC Cable is for use in aerial installations, direct buried, concrete-encased installations, cable trays, troughs or continuous rigid cable supports. These cables are capable of operating continuously at a maximum conductor temperature of 105°C for normal operation, 140°C for emergency overload conditions, and 250°C for short circuit conditions, and are rated at 2,400V in wet or dry locations.

SPECIFICATIONS

Southwire AL09ENS Type MV-105 or MC Cable is manufactured and tested in accordance with the latest revisions of:

- ICEA S-96-659 (NEMA WC 71) – Nonshielded Cables Rated 2001-5000 Volts for Use in the Distribution of Electric Energy.

- UL 1072 – Medium Voltage Power Cables.

- IEEE 1202 – Flame Test (70,000 Btu/hr Vertical Tray Test).

- ICEA T-29-520 – Vertical Cable Tray Flame Tests (210,000 Btu/hr.).

CONSTRUCTION

Southwire AL09ENS Type MV-105 or MC Cable is a flame-resistant product that offers heavy duty construction and flexible EPR insulation. For use in cable trays per NEC Article 392. Optionally, SOLONON™ low smoke, nonhalogen polyolefin jackets and CPE jackets are available upon request.

SCOPE: This specification covers three conductor EPR (ethylene propylene rubber) insulated, non-shielded, interlock armored, thermoplastic jacketed power cables with grounding conductor for use in aerial installations, direct burial, concrete-encased installations, cable trays, troughs, or continuous rigid cable supports. These cables are capable of operating continuously at a temperature of 105°C for normal operations, 140°C for emergency overload conditions, and 250°C for short circuit conditions, and are rated 2,400 volts in wet or dry locations.

STANDARDS: The following standards will form part of this specification:UL Standard 1072 for Medium Voltage Power Cables and ICEA S-96-659 (NEMA WC 71) Nonshielded Cables Rated 2001-5000 Volts for Use in the Distrbution of Electric Energy.

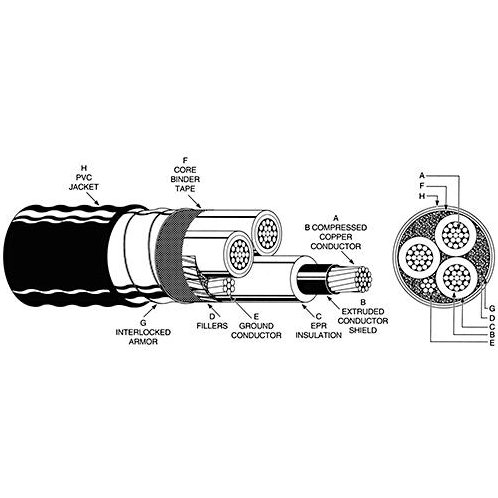

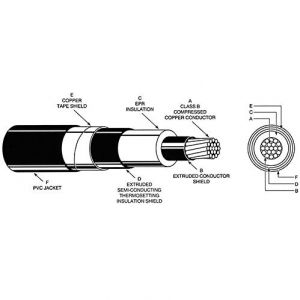

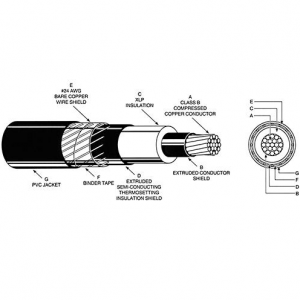

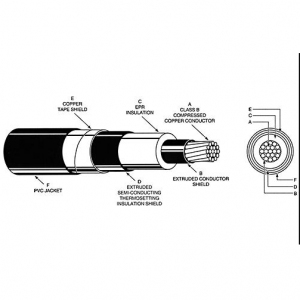

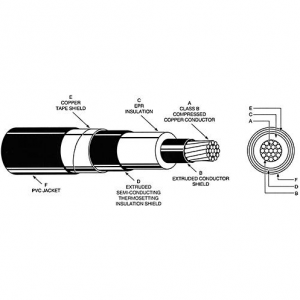

CONDUCTOR: The conductor will be Class B compressed concentric stranded bare copper in accordance with ASTM B3 and B8 and ICEA.

CONDUCTOR SHIELD: The conductor will be shielded with an extruded semi-conducting thermosetting polymeric layer, which will be firmly bonded to the insulation. The thickness will be in accordance with the referenced standards.

INSULATION: The insulation will be EPR (ethylene propylene rubber) meeting the requirements of the referenced standards. The average thickness will be 0.115″ and the minimum spot thickness will be not less than 90% of the average thickness.

GROUNDING CONDUCTOR: The ground conductor will be Class B compressed concentric stranded bare copper in accordance with ASTM B3 and B8.

ASSEMBLY: The insulated power conductors will be cabled round with fillers and with a grounding conductor in one outer interstice and covered with a binder tape.

ARMOR: A single strip of interlocked armor of aluminum will be applied over the assembly.

JACKET: The cable will be covered with a yellow PVC jacket conforming to the requirements specified for polyvinyl chloride in ICEA. The average thickness will be in accordance with the referenced standards and the minimum spot thickness will be not less than 80% of the average thickness. The jacket will be sunlight resistant and will meet the requirements of IEEE 1202 (70,000 BTU/hr.) and ICEA T-29-520 (210,000 Btu/hr.) vertical cable tray flame tests. Optional SOLONON low smoke, non halogen polyolefin jackets and CPE jackets available upon request.

INDENTIFICATION: Manufacturer’s identification will be printed on the jacket.

TESTS: Physical and electrical tests will be conducted in accordance with the requirements of the referenced standards.