Description

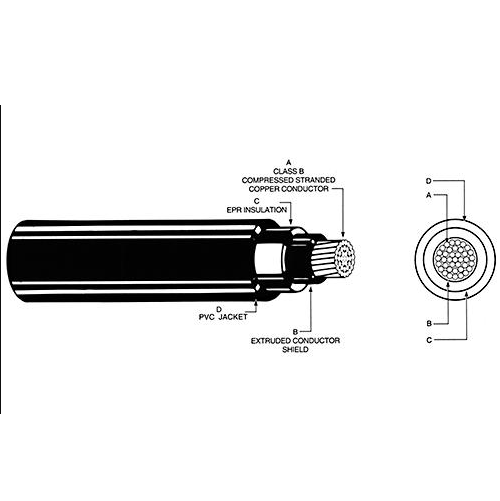

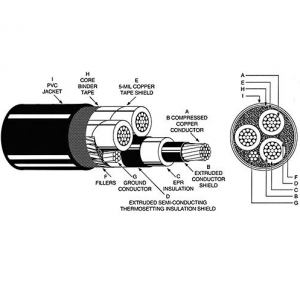

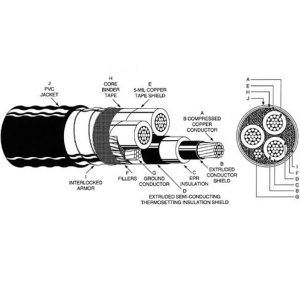

2.4kV Type MV-90. Copper Conductor. Thermosetting Conductor Shield. EPR Insulation. Nonshielded. PVC Jacket. Limited to 2,400 Volts Maximum.

APPLICATIONS

Southwire 09ENS/PVC Type MV-90 Cable is for use primarily in raceways in industrial applications as specified by the National Electrical Code. These cables are capable of operating continuously at a conductor temperature not in excess of 90°C for normal operation, 130°C for emergency overload conditions, and 250°C for short circuit conditions, and are rated at 2,400V in wet or dry locations.

SPECIFICATIONS

Southwire 09ENS/PVC Type MV-90 Cable is manufactured and tested in accordance with the lastest revisions of:

-

- UL 1072 – Medium Voltage Power Cables.

- ICEA S-96-659 (NEMA WC 71) – Nonshielded Cables Rated 2001-5000

Volts for Use in the Distribution of Electric Energy.

CONSTRUCTION

Southwire 09ENS/PVC Type MV-90 Cable offers flexible, easy bending insulation, easy cable preparation, 90°C contiuous operating temperature, resistance to moisture. This product is flame retardant. Also available listed for cable tray use in sizes 1/0 and larger upon request.

SCOPE: This specification covers single conductor EPR (ethylene propylene rubber) insulated, PVC jacketed power cable. This cable is capable of operating contiuously at a conductor temperature not in excess of 90°C for normal operation, 130°C for emergency overload conditions, and 250°C for short circuit conditions, and is rated at 2,400V, wet or dry locations.STANDARDS: The following standards will form part of this specification – UL Standard 1072 for Medium Voltage Power Cable and ICEA S-96-659 (NEMA WC 71) Nonshielded Cable Rated 2001-5000 Volts for Use in the Distribution of Electric Energy.

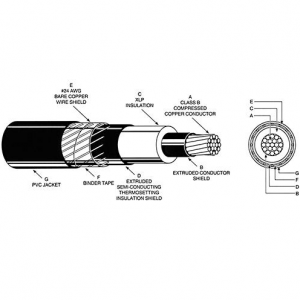

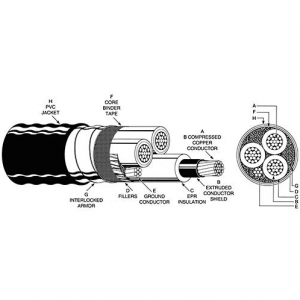

CONDUCTOR: The conductor will be Class B compressed soft or annealed copper in accordance with ASTM B3, and B8 and ICEA Part 2, Section 2.1 and 2.5.

CONDUCTOR SHIELD: The conductor shall be shield with an extruded semi-conducting thermosetting polymeric layer over the conductor, applied in tandem with and firmly bonded to the insulation.

INSULATION: The insulation will be EPR (ethylene propylene rubber) meeting the requirements of the referenced standards. The minimum thickness shall not be less than 90% of the average thickness.

JACKET: The cable shall be provided with a jacket of black PVC conforming to the requirements specified for polyvinyl chloride jackets in UL 1072. The average thickness shall be in accordance with table 4-3 of ICEA, and the minumum spot thickness shall not be less than 80% of the average thickness 1.

IDENTIFICATION: Cable shall be identified by surface printing on jacket.

TESTS: Physical and electrical tests shall be conducted in accordance with the requirements of UL Standard 1072 and ICEA S-96-659 (NEMA WC 71).

AVAILABLE ALTERNATIVES: Upon request, cable is available in sizes AWG 1/0 and larger listed for use in cable trays.

1 For NEC when requested.