Description

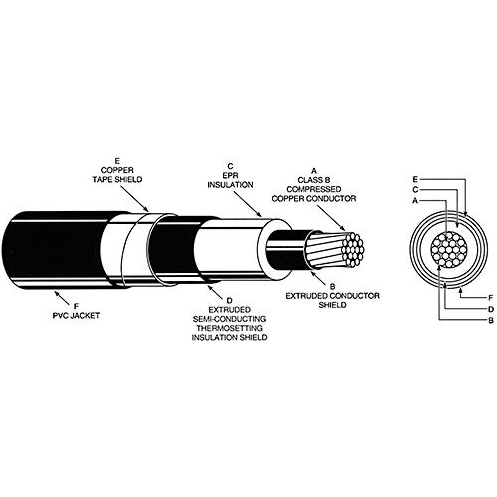

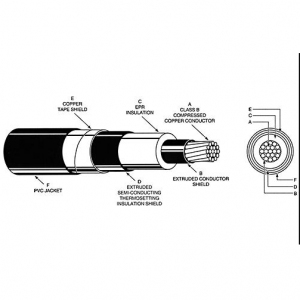

35kVU Type MV-105. Copper Conductor. Thermosetting Conductor Shield. EPR Insulation. Thermosetting Insulation Shield. Copper Tape Shield. PVC Jacket. Listed for CT Use.

APPLICATIONS

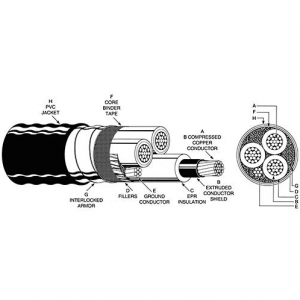

Southwire CT1-21ET Type MV-105 Cable is for use in aerial, direct burial, cable trays, conduit, and underground duct installations as permitted by the National Electrical Code. These cables are capable of operating continuously at a conductor temperature not in excess of 105°C for normal operation, 140°C for emergency overload conditions, and 250°C for short circuit conditions, and are rated at 35,000V, 133% (ungrounded system) .

SPECIFICATIONS

Southwire CT1-21ET Type MV-105 Cable is manufactured and tested in accordance with the latest revisions of the following standards and specification:

- UL 1072 – Medium Voltage Power Cables.

- ICEA S-93-639 (NEMA WC 74) – 5-46 kV Shielded Power Cable for Use in the Transmission & Distribution of Electric Energy.

- ICEA S-97-682 (when requested) 5-46 kV Standard for Utility Shielded Power Cable.

- UL 1685 – (AWG 1/0 and larger) – UL Flame Exposure Test.

Certified qualification tests were performed in accordance with the requirements of AEIC CS-8. Cable has fully met the qualification testing requirements of AEIC CS-8.

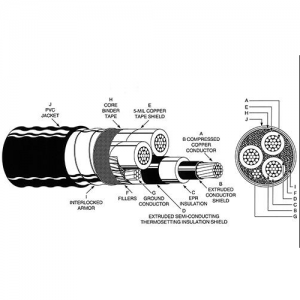

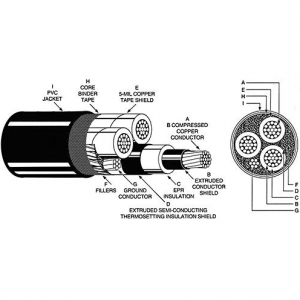

CONSTRUCTION

Southwire CT1-21ET Type MV-105 Cable offers flexible, easy bending insulation, easy cable preparation, fast stripping thermosetting insulation shield, 105°C continuous operating temperature, 100% shield coverage, and it is triple extruded. Cable is sunlight resistant, suitable for direct burial, and listed for cable tray use in sizes AWG 1/0 and larger. SOLONON™ low smoke, non halogen polyolefin jackets and CPE jackets are available upon request.

Scope: This specification covers single conductor EPR (ethylene propylene rubber) insulated, shielded, thermoplastic jacketed power cable for use in aerial, direct burial, cable trays, conduit, and underground duct installations. This cable is capable of operating continuously at a conductor temperature not in excess of 105°C for normal operation, 140°C for emergency overload conditions, and 250°C for short circuit conditions, and are rated at 35,000V, 133% insulation level (ungrounded system).

Standards: The following standards shall form a part of this specification – UL Standard for Medium Voltage Power Cable and ICEA S-93-639 (NEMA WC 74) 5-46 kV Shielded Power Cable for Use in the Transmission and Distribution of Electric Energy.

Conductor: The conductor shall be Class B compressed soft or annealed copper in accordance with ASTM specs B3 and B8 and ICEA Part 2, Section 2.1 and 2.5.

Conductor Shield: The conductor shall be shielded with an extruded semi-conducting thermosetting polymeric layer over the conductor, applied in tandem with and firmly bonded to the insulation.

Insulation: The insulation shall be EPR (ethylene propylene rubber) meeting the requirements of the referenced standards. The nominal thickness shall be 0.420″.

Insulation Shield: The insulation shall be shielded with an extruded layer of semi-conducting thermosetting material which shall be identified as being semi-conducting. Over this layer shall be applied a helically-wrapped 5-mil copper tape with 25% overlap.

Jacket: The cable shall be provided with a jacket of black sunlight resistant PVC conforming to the requirements specified for polyvinyl chloride jackets in ICEA. The average thickness shall be in accordance with Table 7-3 of ICEA. Optional SOLONON low smoke, non halogen polyolefin jackets and CPE jackets are available upon request.

Identification: Cable shall be identified by surface printing on the jacket.

Tests: Qualification tests shall be conducted in accordance with the requirements of AEIC.